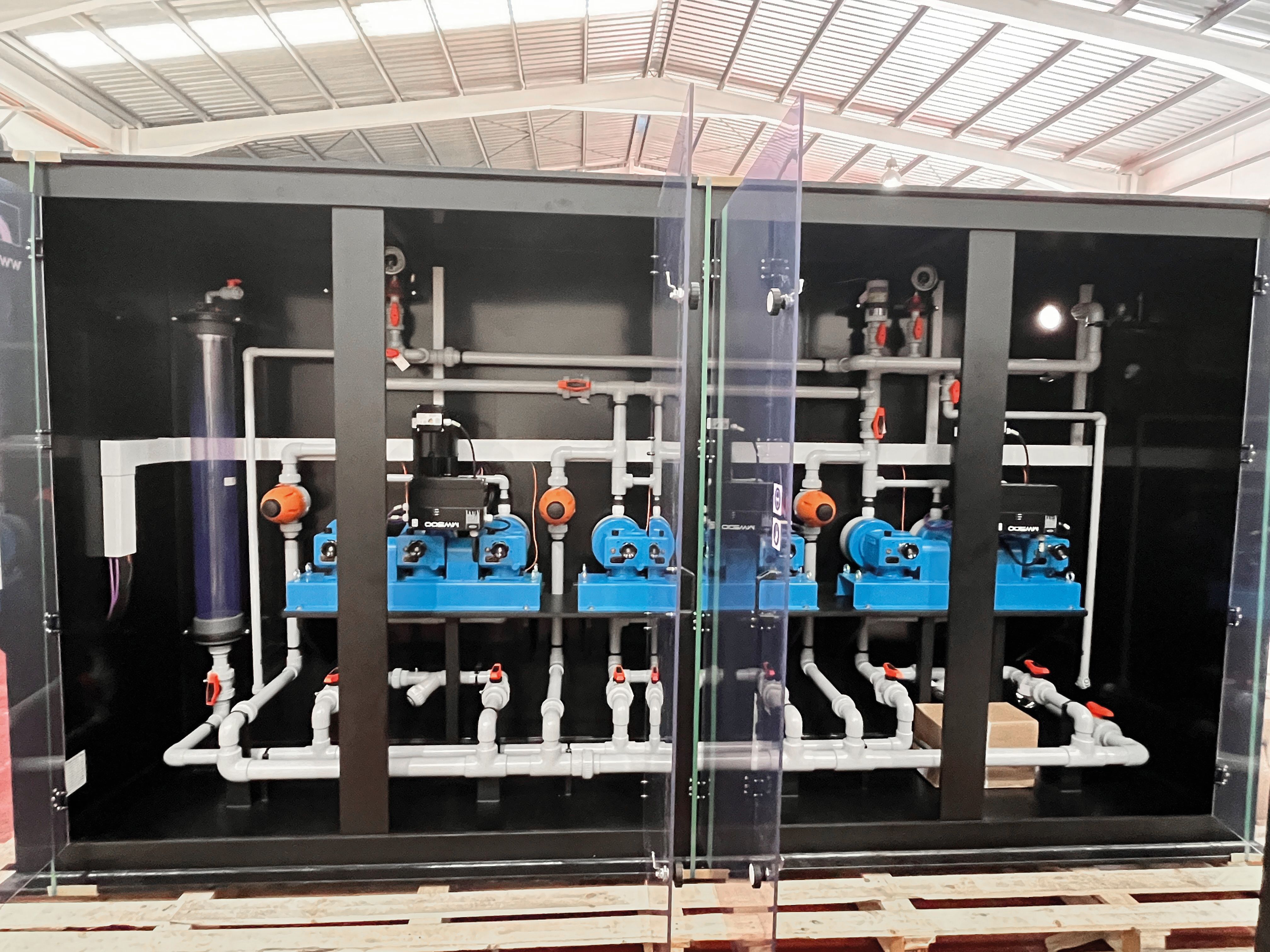

The industrial production of butter requires precisely coordinated process control. One critical aspect is the dosage of water, brine and bacterial cultures – these not only influence the desired product type (e.g. sour cream butter or salted butter), but also compliance with legal limits. In particular, the water content must not exceed 16%. sera has supplied various pump systems in hygienic design for a renowned manufacturer of continuous churning machines, which dose different media at operating pressures of up to 5 bar while the process is running.

Technical realisation

Several dosing points are used in butter production:

- Addition of bacterial cultures

Mixed cultures of mesophilic lactic acid bacteria are added to produce sour cream butter. In addition to acidification, these also have an influence on flavour formation. An iSTEP S20 in hygienic design with tri-clamp connection is used for this purpose.

Dosing of brine

Type F17 and F28 peristaltic pumps are used for the production of salted butter. Here, too, the connection is made via Tri-Clamp.

Setting the water content

The precise addition of drinking water takes place via F17 and F12 peristaltic pumps in order to comply exactly with the legally prescribed maximum value.

- Detergent and disinfectant dosing

Wall dosing stations with suction lances were also installed to dose cleaning and disinfectant media such as caustic soda or hydrogen peroxide solution, thus contributing to the hygienic safety of the entire system. - Functional requirements

- All pump components used fulfil the requirements for hygiene (tri-clamp connection, conformity of materials in accordance with Regulation EC 1935/2004), pressure stability (up to 5 bar) and exact dosing quantities. The peristaltic pumps are easy to maintain and therefore ideal for frequent media changes and flexible cleaning cycles.

- Butter production places high demands on process safety and hygiene. With the pump technology supplied, sera helps to ensure that all relevant media are precisely dosed – for reproducible and convincing product quality, safe food and stable operation in a continuous process.