sera customers are used to placing an order and receiving a dosing system designed according to their requirements on the agreed date. Perhaps he has spoken to the responsible sales colleague or even a design engineer on the phone once or twice to clarify details. But has he ever asked himself who the people are who have worked on his system? Which departments and people accompany his dosing system until it leaves our factory? This is exactly what we will show today.

As an example, we will follow the path of a dosing system that a system supplier for breweries ordered from us.

SALES

The path of our dosing system starts quite classically with an enquiry from the customer to our sales department. In this specific case, a solution for CIP cleaning was required on the one hand, and on the other, dosing systems to ensure consistent water quality in the brewery – in short: with our product solutions, we ensure that the brewed beer really tastes like beer. This is an extensive project that is managed by sera’s Food & Beverage team.

Of course, the Sales Application Manager knows immediately which dosing systems are the right ones for this project. With hundreds of possible combinations of pumps, materials and applications in the sera modular system, this is not easy – but it is no longer a challenge for our experts.

The suitable systems are designed on the computer: three CVDs (Compact Vertical Dosing) for CIP cleaning in the brewing process and two dosing systems each for dosing phosphoric acid (H3PO4) and for preparing calcium chloride (CaCL2). Based on these designs, the sales representative now prepares the offer for the customer. Since we at sera attach great importance to personal customer contact, a customer visit usually takes place for customer-specific systems, during which the offer is discussed in detail once again and open questions can be clarified.

KICKOFF

After the order has been placed by the customer, the sales colleague as project manager gathers all the colleagues involved from the design, purchasing, order centre and sales departments in a kick-off meeting. For this purpose, he has provided the colleagues with all the information about the project in preparation. Together they discuss the further procedure and agree on a schedule. Our three CVDs are only briefly discussed, as they are standard systems from our modular system. The other dosing systems, however, are customised solutions and thus require special consideration: On the one hand, special components such as tanks have to be purchased, and on the other hand, the systems have to be designed specifically. In exchange with each other, a time schedule and an expected delivery date for the customer are determined. With the results of the KickOff meeting, it is now possible for the sales department to confirm the customer’s order with a delivery date.

CONSTRUCTION

The customised systems are now designed on the basis of the order. Our designers sit together with the sales department in an airy open-plan office – so queries can be clarified quickly.

The diversity of plant technology and the most varied customer specifications are the major challenges in the work of our designers – but they are happy to meet them and, thanks to their comprehensive know-how and technical experience, they always find the right individual solution. This was also the case in our case: within a few days, the four customised plants required for the preparation of calcium chloride (CaCL2) and the addition of phosphoric acid (H3PO4) were constructed. After technical approval by the customer, the design department hands over the final design drawings with the corresponding parts lists to the order centre.

ORDER CENTRE

Parallel to the construction, the work of the order centre already begins. After the kick-off meeting with the relevant departments, the order centre enters the project into our ERP (Enterprise Resource Planning) system. In addition to the design drawings of the standard systems, a list of components and a time schedule are now available there. Via the system, the colleagues in the order centre are able to see the overall order situation and thus also the utilisation of the individual production units. In this way, they can schedule the parts and work steps required in each case, according to the project’s deadline. The order centre is in constant communication with the purchasing department and the production areas and can thus plan when which work steps are to be carried out on the equipment and also controls any adjustments or delays.

PRODUCTION PREPARATION

sera stands for quality and a high level of production depth. This means that many components of our systems are manufactured by us and not bought in. Whether sawing, turning, welding or painting – we like to do it ourselves to ensure high, consistent quality. For example, pump bodies, nozzles and much more are manufactured on our CNC machines. The colleague at the machine not only monitors the work, but also programs it.

Depending on the order, the seranian receives a dimensional drawing of the required component and then creates the corresponding programme for the parts. This requires the utmost concentration and precision; after all, there should be no deviations. That’s why we always work according to the 4-eyes principle at our CNC production stations. Finished parts are checked, measured and rechecked. This applies to all parts: Individual and series parts, made of metal or plastic. Only then are the finished individual parts transferred to the next station.

PAINTING

To the paint shop, for example. Here, our painters ensure that our pumps arrive at our customers in the unmistakable sera blue – and always with consistently high quality. In addition to pump housings, drive housings and base rings, our large compressors are also painted here – the biggest challenge, but nevertheless no problem for the skilled painters and varnishers.

The finished painted parts are then transferred to our stock in order to be directly available for projects. As soon as they are transferred to the ERP system, they are automatically available for all further work steps.

MATERIAL MANAGEMENT

As soon as all the required parts, whether bought in or manufactured at sera, are available, material management comes into play. Our small parts warehouse contains more than 7,500 different items – yet the colleagues on site still have an overview.

Equipped with the parts list from the order centre, a warehouse employee picks all the individual parts of our dosing systems – the containers procured by the purchasing department as well as the pump housings milled at sera in production preparation and painted in the paint shop and dozens of other components such as pipes, screws, fittings and much more. It starts with the commissioning of the individual parts required for the respective dosing pumps, as these are needed as fully assembled components of the dosing systems.

PUMP ASSEMBLY

First, all the parts for the dosing pumps installed in the dosing systems end up in our pump assembly department. There, each employee assembles up to 15 pumps daily. This also applies to the diaphragm pumps installed in our dosing systems: two RF410.2-570e, two RF410.2-280 and three RF409.2-140e. Each individual pump is assigned the appropriate parts by a Kanban system. All parts to be installed – depending on the pump type, more than 50 individual parts – as well as the assigned order with parts list are located on trolleys. With thousands of possible pump combinations, this is essential to ensure that exactly the pump the customer needs for his project is built. Before assembly begins, the fitter checks once again that all the parts needed for production have been provided. His job requires a lot of skill and concentration; some of the individual parts are very small, so the work must be carried out in a filigree manner. Finally, the fully assembled pumps are tested on the test bench for functionality and safety, and after successful testing they are reported „ready“. This message is the release for the order centre to initiate the next work steps:

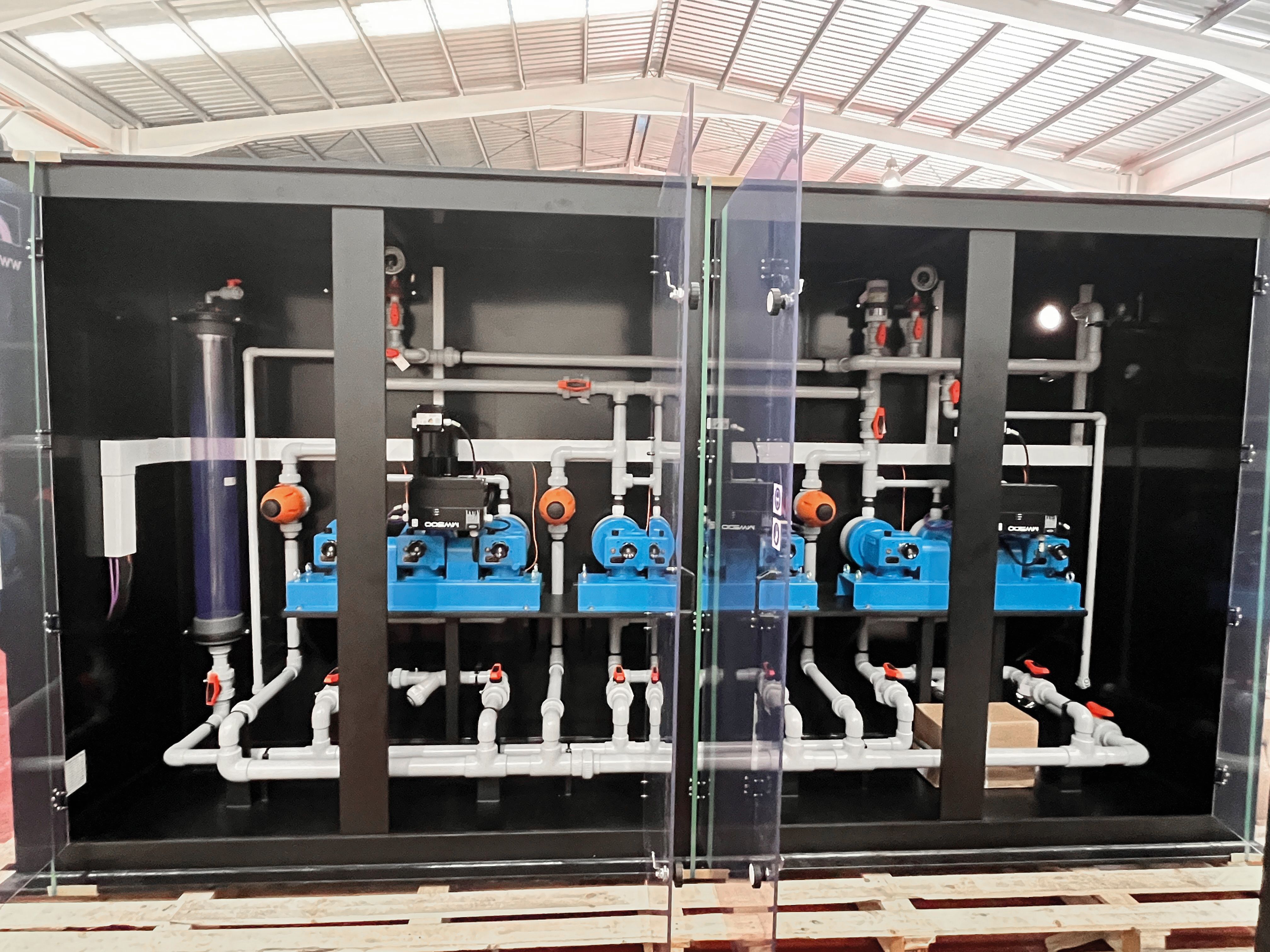

PLANT CONSTRUCTION

After successful testing, the pumps are collected by material management and assigned to the respective order. Together with all prepared parts, they are then brought to our plant construction department – again order-related. Here, the next seranian is already ready to assemble and weld the individual parts of the dosing systems. First, he welds the walls milled at our plant to form a wall mounting plate with a collecting tray and drainage nozzle. In the next steps, he mounts all the other individual parts planned and commissioned for the system, such as piping, pumps, fittings, ball valves and valves, on this plate. In accordance with the 4-eyes principle

In accordance with the four-eyes principle, the production manager always checks in between: Do the parts that he has received from the warehouse correspond to the parts list of the production order? If, during the construction of the system, any discrepancies should come to light that affect the design of the system, they are immediately reported back to the design department. This ensures the consistently high quality of our systems.

ELECTRICAL ASSEMBLY

After the system has been equipped with a type plate and works number, as well as our sera logo, the last work step in system construction is the leak test of our dosing systems. Our plastic systems are tested with water at 5 bar as standard. If everything is in order there as expected, the work of the electricians begins – they make sure that all electrical connections of the system are correct. Switches, controls or switch cabinets are installed and then tested for safety. In addition to the alignment with the customer’s order, the electrician also carries out the high-voltage test, an insulation measurement and a protective conductor path test according to the VDE standard.

QUALITY ASSURANCE

All upstream tests in pump assembly, plant construction and electrical assembly have now been completed, all tested areas entered in the test report and signed off by colleagues. Now quality management comes into play. This department is responsible for ensuring that our dosing systems and all other sera products only leave the factory if they meet all customer requirements and are completely flawless. A final inspection is carried out for this purpose. This takes place, like the entire production process, on the basis of the ISO 9001:2015 standard. Thanks to complete documentation, quality management knows which systems are in front of it and also that there has already been a function and safety test for the installed pumps and a leak test for the entire system. With the help of the production order and the sera test protocol, the quality manager now compares the system that was created on paper with the system that is now ready in front of him: Do the parts installed with factory numbers, such as pumps, match the factory numbers in the production order? Have the colleagues carried out the formal inspections of the pumps and systems, noted them down and signed them off? Yes, everything has been checked correctly and all the plant numbers match.

Next, the dimensions of the plants are checked and compared with the drawings. All connections were set correctly and special dimension requests from the customer were also complied with. Another quality point that can be ticked off in the inspection report. During the subsequent visual inspection, any last chips or shields are removed, or even a screw is covered up – so that the system looks as flawless as it will function.

The quality inspection concludes the quality management with the official release: On the one hand, the plant is given a „released“ sticker with the plant number, inspector and date, and on the other hand, the entire order is reported as finished in the system. This is how QM initiates the final steps of our dosing system at the sera plant.

DISPATCH DEPARTMENT

The plant is reported ready in the system. While the documentation – customer-specific – is being issued, a logistics employee collects the systems from the plant construction department. In the outgoing goods department, the small dosing systems are stowed in sera transport containers and the systems with containers find their transport place in corresponding transport boxes. All export papers and shipping documents are available in multiple copies and this is how the journey of our dosing system ends at sera: well packed and safe for transport, the total of seven dosing systems are now collected by a shipping company and set off on their long journey to do their job in a brewery and ensure that the brewed beer really does taste like beer.

Learn more about our dosing systems: Dosing systems | sera GmbH (sera-web.com)