Water is one of the most valuable resources of our time – especially in regions where every drop counts. The Shu-weihat S4RO project in Abu Dhabi is creating one of the most modern seawater reverse osmosis (SWRO) plants in the world.

The international company GS Inima is responsible for the development and operation of the plant, which has an impressive daily production capacity of 318,226 cubic metres of drinking water for the Emirates Water and Electricity Company EWEC). GS Inima relies on tailor-made systems from sera Tecnología Iberia S.L. for the safe and efficient treatment of this water. The Spanish branch of the sera Group was commissioned with the design, manufacture, testing and commissioning of the chemical and polyelectrolyte treatment system – a contract that further consolidates sera Iberia’s strong market position in international water treatment.

Customized solutions for extreme conditions

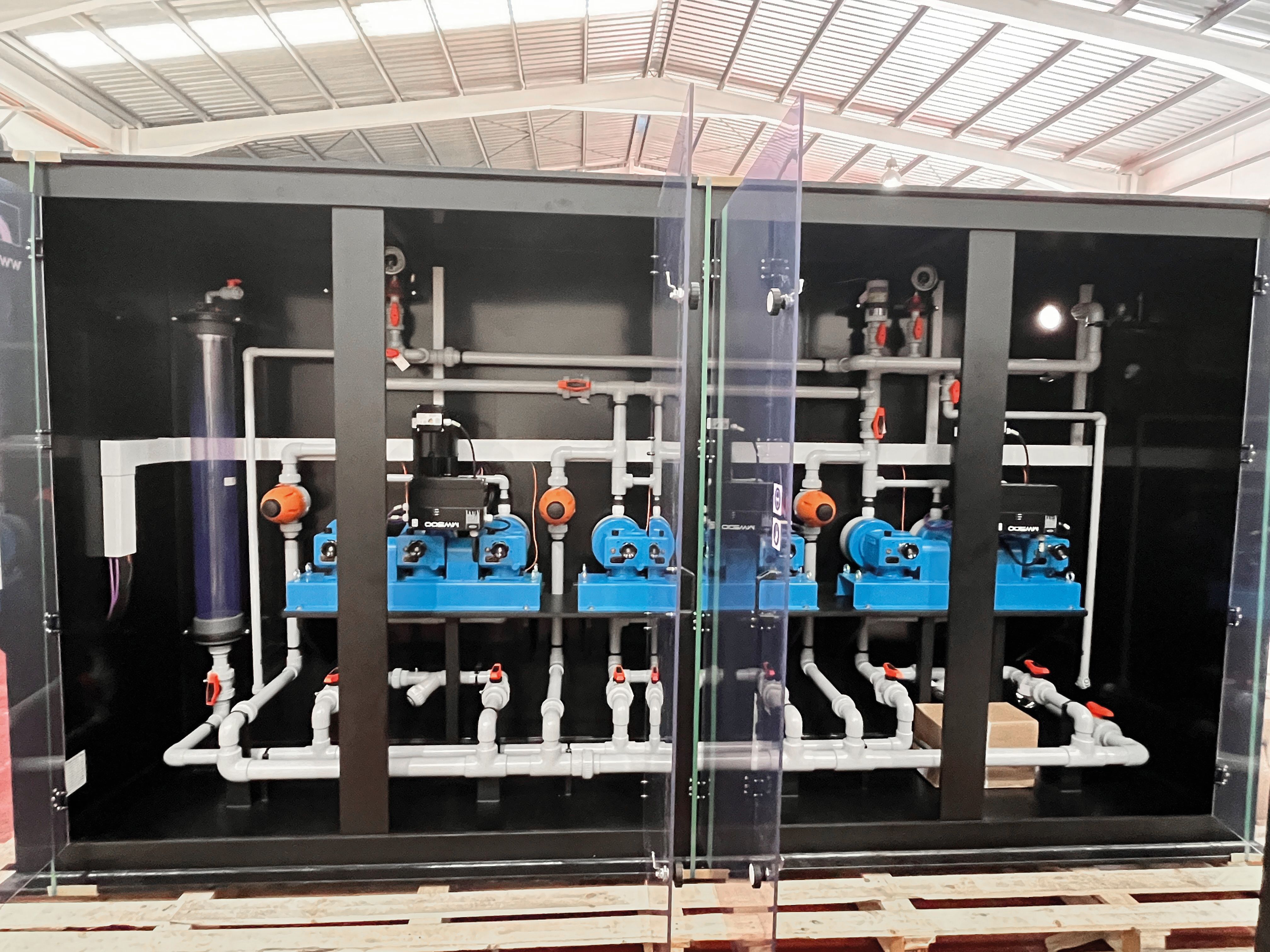

What sets sera apart from other suppliers is its combination of technical expertise, flexibility and innovative strength. An experienced team of engineers develops individual solutions for each project – always with a view to the specific requirements on site. The Shuweihat project also focused on close cooperation with the technical departments of GS Inima in order to ensure maximum efficiency and reliability. High-performance pumps from sera are used at the heart of

the plant. They are specially designed for operation under the extreme climatic conditions of Abu Dhabi – with motors for high ambient temperatures, robust special coatings and multi-head configurations with a capacity of up to 4,500 litres

per hour. This ensures precise and stable delivery even under the most demanding conditions.

Quality produced in-house

A special feature of sera Iberia is that it manufactures all systems entirely in-house. Since its foundation over ten years ago, the company has developed into a leading provider of integrated solutions, developing, manufacturing and programming all electrical control systems internally. This independence from external suppliers enables the highest quality and flexibility – and at the same time strengthens the innovative power within the entire sera Group.

Innovation meets sustainability

sera also relies on state-of-the-art processes in the field of connection technology: at the customer’s request, infrared welding technology was used for PVDF piping systems for the first time in the Shuweihat project. sera has the appropriate IR

welding certification, which guarantees robust, fully traceable connections and virtually eliminates the risk of leaks – an important contribution to operational safety and resource conservation.

Commitment to the future

With projects such as Shuweihat, sera underlines its commitment to sustainable water treatment worldwide and consolidates its position as one of the leading companies in the development and manufacture of dosing systems for desalination

plants. Whether in Abu Dhabi, Spain or Germany – the sera Group stands for efficiency, reliability and quality from a single source. The successful collaboration with GS Inima shows once again that when innovative and reliable solutions are

required, sera is the right partner.