How innovative technology increases sustainability and efficiency! Water is the basis for many industrial processes – and its quality plays a key role in the production of chemicals. A plant in Poland is an impressive example of how modern water treatment systems can increase production reliability and support sustainability goals.

From river to plant

The plant draws its process water directly from a nearby river. However, this water is not immediately usable – it must first be treated. In the first step of the treatment, larger impurities are removed by precipitation and flocculation processes.

Special chemicals such as iron (III) chloride are used to destabilise suspended solids and promote their aggregation into larger particles that can then be separated. This pre-treatment improves the water quality and creates optimal conditions for the subsequent treatment steps.

The water is then subjected to a process to reduce the hardness. This is done in a targeted manner to prevent deposits and corrosion in the systems. These measures not only ensure the quality of the production water, but also protect the sensitive system components.

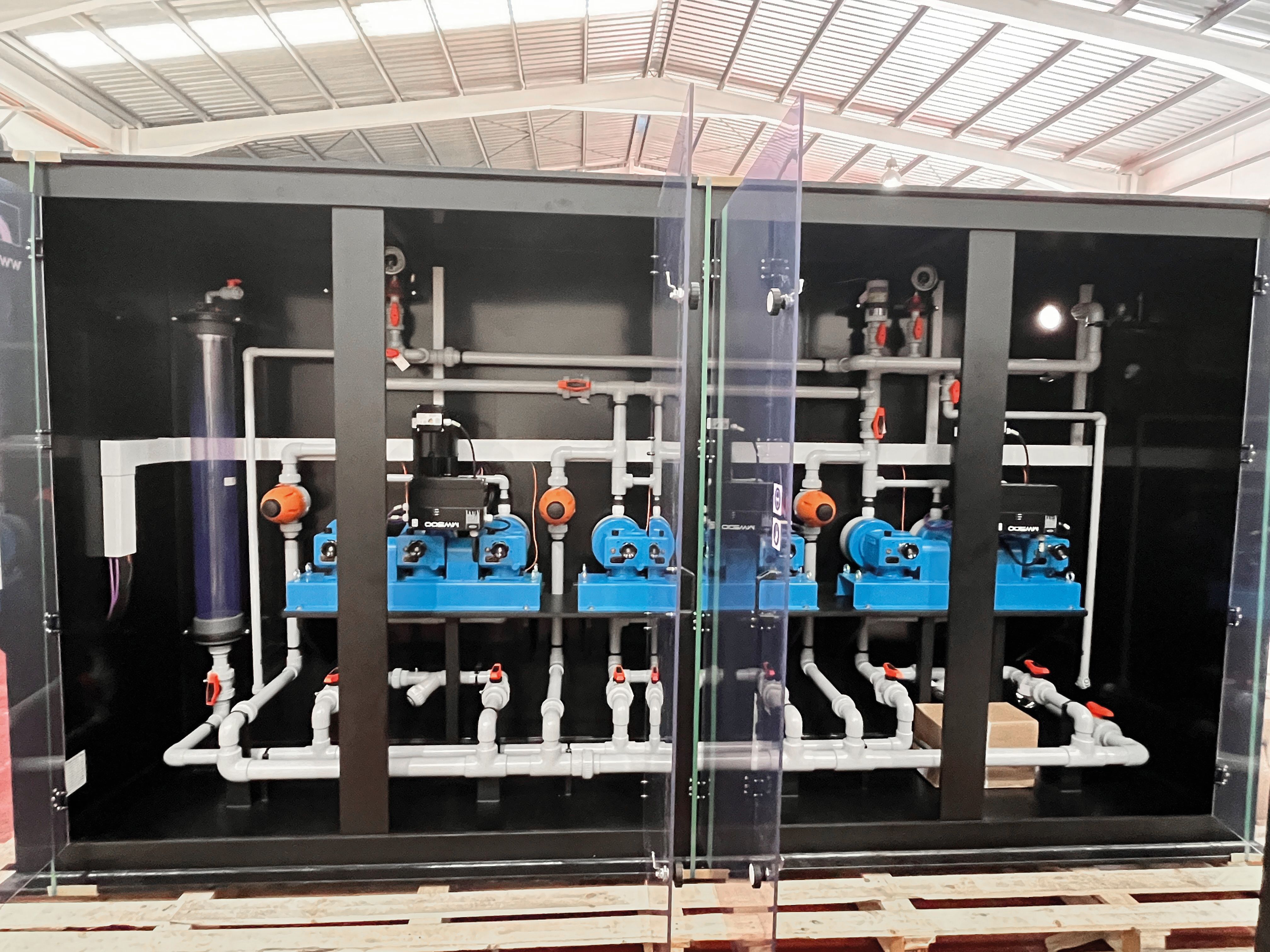

The key role of sera dosing technology The precise dosing systems from sera are a central element of this system. These provide exact dosing of chemicals such as iron (III) chloride and sulphuric acid. Iron (III) chloride ensures that suspended matter is precipitated, while sulphuric acid is used to neutralise the pH value after sedimentation.

Thanks to the high precision of the sera systems, the water quality remains constantly at the desired level, which increases the efficiency of the entire system. In addition, two sera polymer preparation stations are used. They produce and dispense special polymer solutions that further improve the flocculation process. These technologies optimise sedimentation and help to further increase the purity of the water.

Modern control for maximum efficiency

All dosing systems are integrated into a modern control system. This allows the supply of chemicals to be monitored and adjusted in real time. This automation not only ensures safe operation, but also helps to minimise chemical consumption

– a win-win situation for the environment and operating costs.

Optimal use of treated water

The treated water is finally divided into two streams: one part is fed directly into the production process, while the other is further processed into boiler feed water. Both uses ensure a reliable water supply for the plant.

Conclusion: efficiency meets sustainability

With its combination of innovative dosing technology, automated control and a well-thoughtout treatment process, this plant shows how industrial efficiency and environmental responsibility can go hand in hand. sera’s technologies

play a crucial role here – not only do they ensure consistent water quality, but they also extend the service life of the production facilities and reduce operating costs. A prime example of sustainable chemical production!