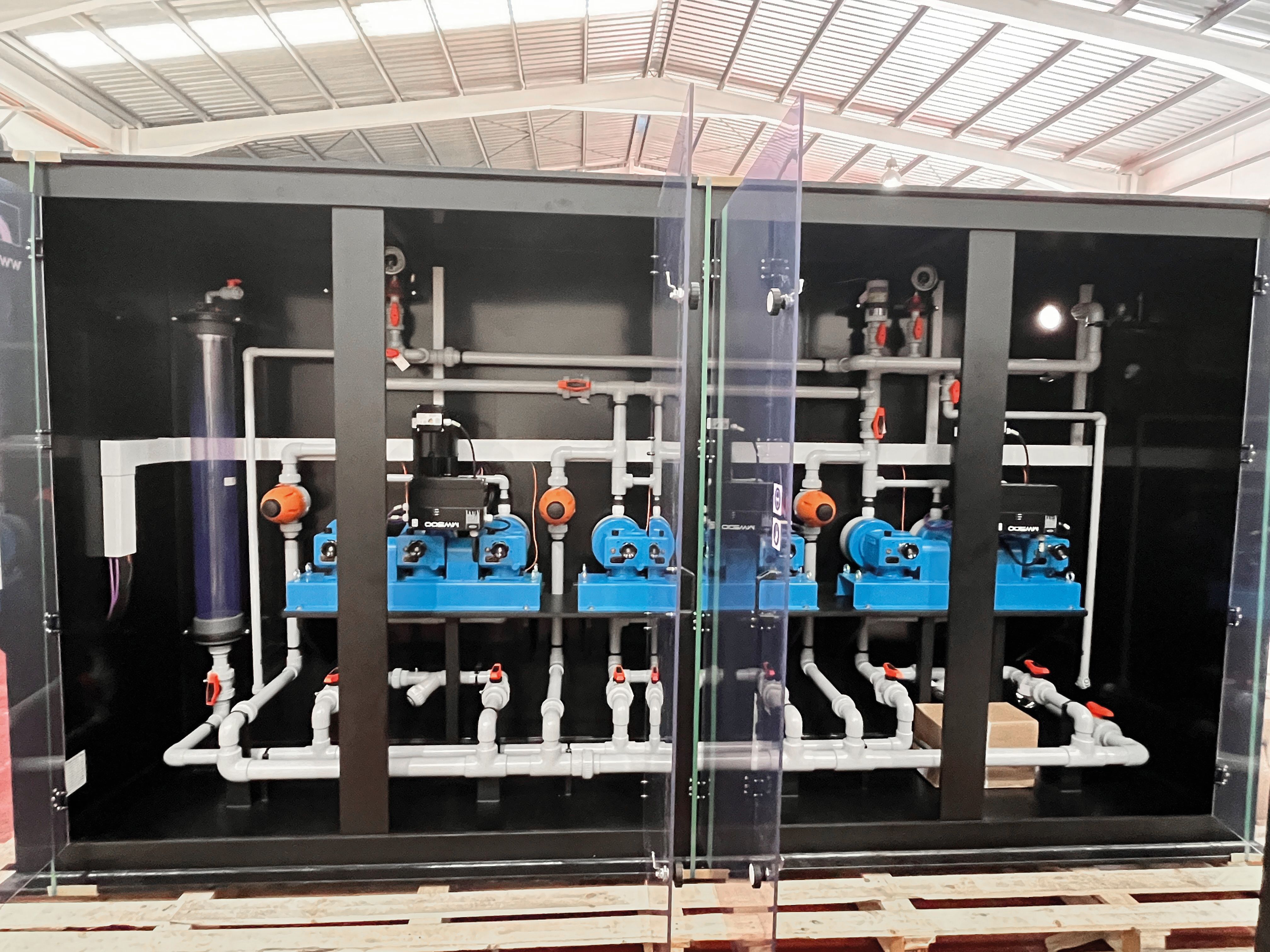

sera has implemented a state-of-the-art CO2 compression plant for the Linde Group, which will be used in Ireland in future. The aim of the project was to provide CO2 of the highest

purity for cleaning sensitive electronic components – around the clock.

Focus on precision, purity and reliability

The gas is compressed from 6–8 bar to 60 bar and then stored in a tank. Three metal diaphragm compressors from the PU series are used, two of which run continuously

while the third is on standby as a backup. This concept ensures maximum system availability – even during maintenance work, the process remains stable and uninterrupted.

The technical requirements are high: the CO2 must not be contaminated in any way during compression. This is where sera’s metal diaphragm compressors show their strengths. They operate without lubricants, abrasion or leakage – for absolutely contamination-free compression. They also impress with their high corrosion resistance, long service life and hermetically sealed system design, which does not require flushing or barrier gases.

„Our technology is the right choice, especially for applications where maximum gas purity is essential. Our compressors combine efficiency, safety and precision – exactly what Linde needs for this process“ explains Roland Tittel, Managing Director of sera HYDROGEN GmbH. With this plant, sera once again demonstrates how innovative compression technology from Immenhausen sets global standards – for maximum purity, reliability and sustainability in sensitive industrial processes.