We are experts in the field of sewage sludge conditioning. That is why we were commissioned to design and deliver a preparation station for polymeric flocculants as part of the construction of the new mechanical sludge thickening plant at the Flensburg sewage treatment plant.

The treatment of wastewater produces sewage sludge, the disposal and utilisation of which is the responsibility of the plant operator. The aim here is to reduce the volume of sludge and increase the dry matter in order to simplify further utilisation and minimise operating costs. In the mechanical sludge thickening process in the belt thickener, the thin sludge is conditioned and filtered by adding polymeric flocculants. The sludge water released between the flocs runs off through the filter fabric of the belt thickener as filtrate, while the flocculated solids are retained on it.

Customised systems

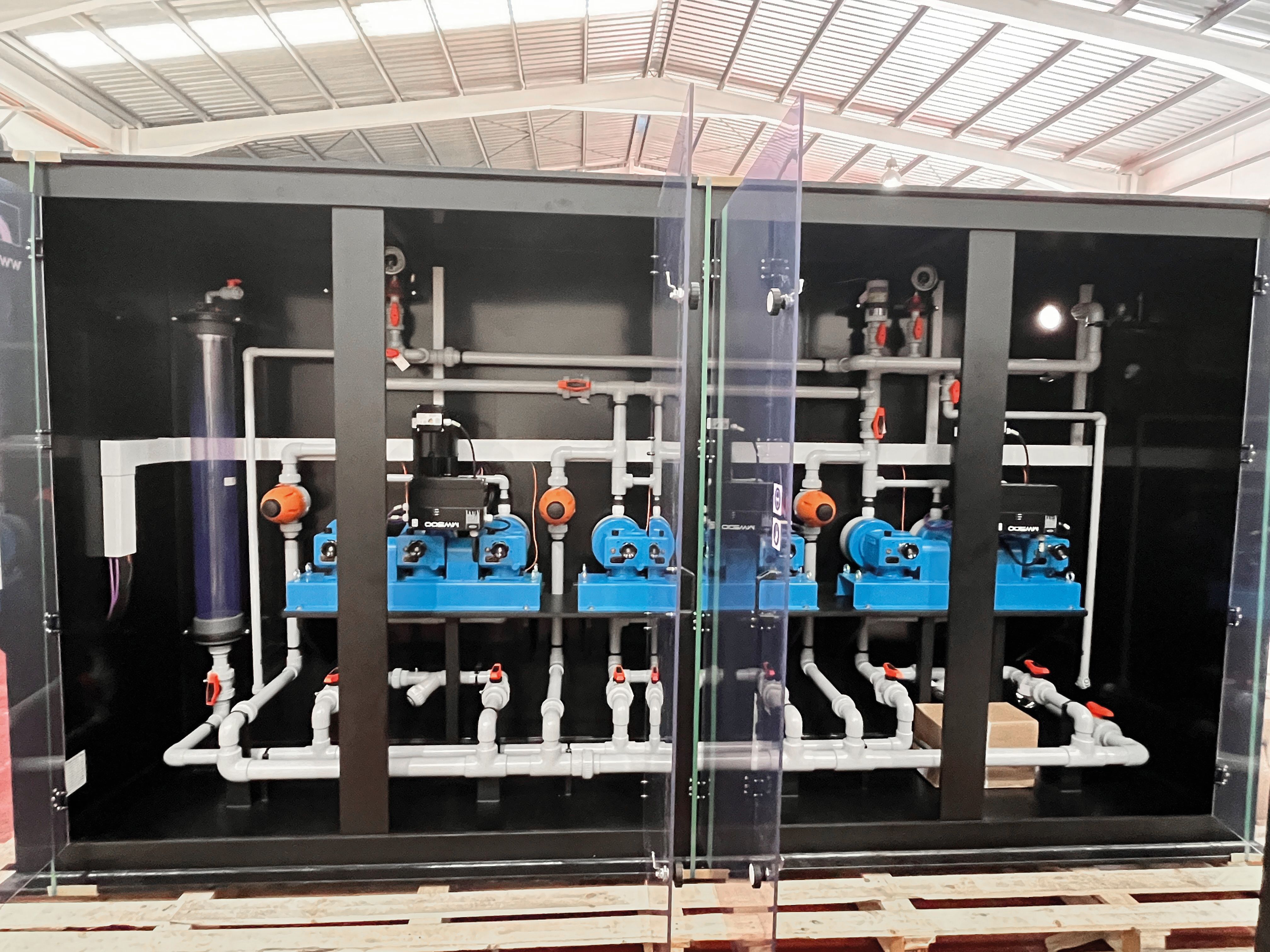

sera supplied a customised 2-chamber pendulum system for preparing and adding the polymer flocculants. The system, which is made entirely of stainless steel, has two preparation tanks, each with a useful capacity of 2 m³. While water and polymer concentrate are prepared in one chamber at the previously determined concentration and then allowed to mature, the other chamber is ready for use. Our system ensures that the polymer flocculant is always prepared in the correct ratio and at a consistent quality, and is dispensed as a stable solution.

Two eccentric screw pumps with dry-running protection and overpressure protection convey the optimally matured polymer solution to the belt thickener or to the mechanical sludge thickening process. Ease of operation, maintenance and servicing were very important to the customer. Therefore, the tanks were supplied with lids in a special size to ensure easy access. In addition, the preparation system was equipped with a customised control system with a large 9’ colour panel and integrated into the central process control system of the sewage treatment plant with the automation and control system of the mechanical sludge thickening system. This enables decentralised monitoring and control of the polymer preparation station.

Significant reduction in flocculant consumption

The installation of the new mechanical sludge thickening plant has significantly increased and optimised both operational reliability and throughput capacity. In addition, the consumption of flocculation aids has been significantly reduced, while at the same time the final dry content of the thickened sludge has been significantly increased to 6 – 8 %.

The new mechanical sludge thickening plant will make a significant contribution to reducing the energy and operating costs of the Flensburg sewage treatment plant in the future – thanks in part to the polymer preparation station supplied by sera.