The beverage industry in Ethiopia is on the upswing. Not only water bottlers and soft drink producers report increased demand, breweries are also benefiting. After the Ethiopian government increasingly banned advertising for alcohol at the end of the 2010s and imposed an increased excise duty on beer – the most popular alcoholic beverage in Ethiopia – the previously continuously rising growth rates dropped significantly. The corona pandemic also played its part.

Since 2021, however, the Ethiopian beer market has increased noticeably. With the beginning of 2022, beverage producers and suppliers to the beverage industry became bolder again and invested in large-scale projects in the country.

This is also the case with Kegna Beverages Share Company, founded in 2017, which aims to become one of the leading companies in the beverage industry in Ethiopia and beyond. To get close to this goal, but above all to quench Ethiopians‘ thirst for beer, Kegna decided to build a brewery about 80 km away from the Ethiopian capital Adis Ababa. With Steinecker GmbH, Kegna commissioned an experienced equipment supplier and market leader in the field of brewing technology to expand their brewery. Steinecker, part of Krones AG, again relied on sera’s expertise to supply the dosing technology required, especially for cleaning the brewing equipment:

1. Production of liquid lye and transport of the liquid lye

Since lye in liquid form is not always available, lye in solid form (flakes, beads) is prepared in a specially designed stainless steel container with a chute for the safety of the cleaning processes. The container and all accessories are of course designed for the exothermic reaction that occurs. The further transport of the hot lye is carried out with a multi-layer diaphragm pump to the on-site receiving tank, from which a sera centrifugal pump feeds the on-site ring line system.

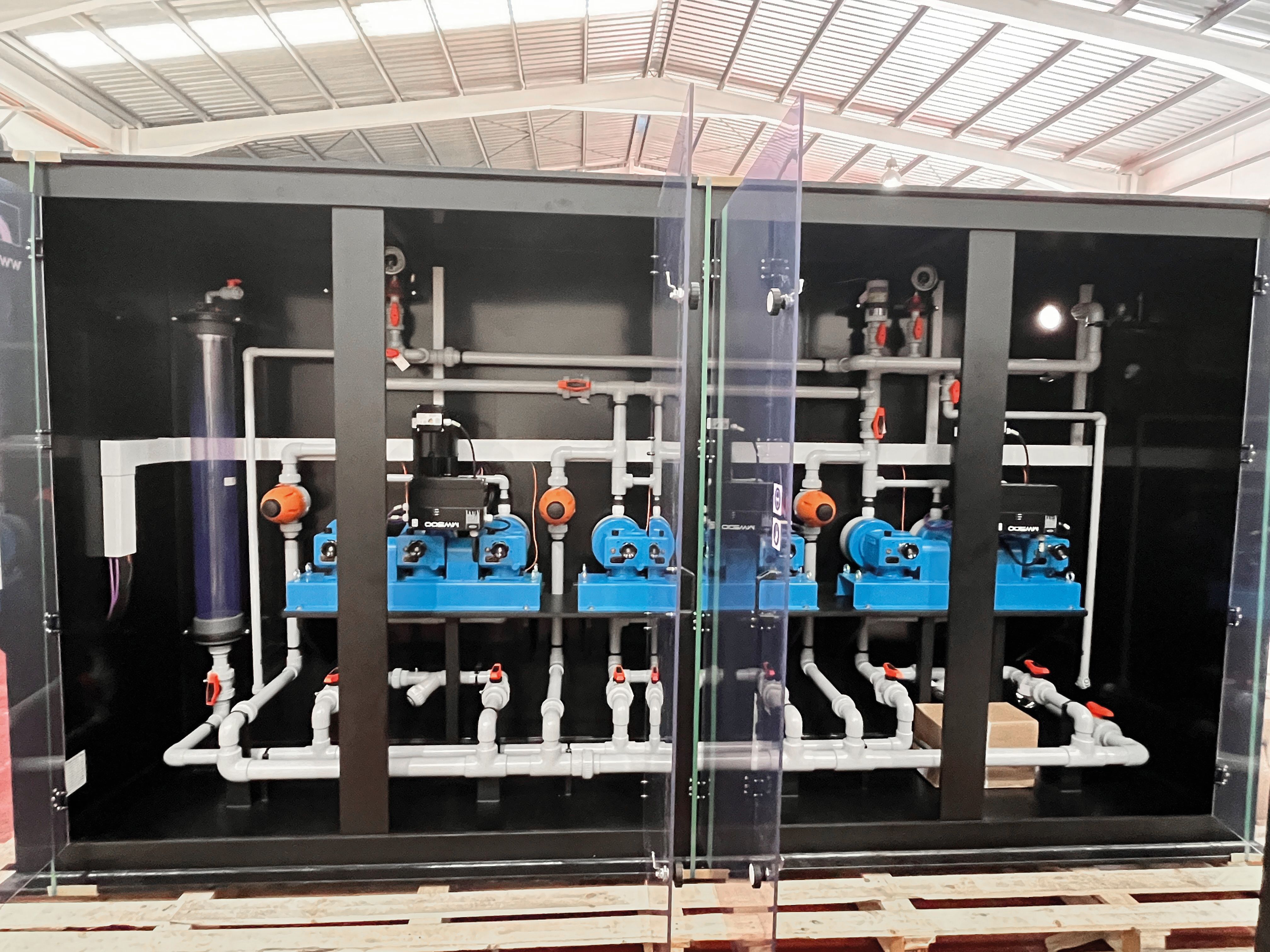

2. Truck emptying, storage, dosing and distribution of acid

The scope of delivery for the acid area includes the truck emptying to the storage tank as well as a double-walled storage tank with all necessary monitoring, filling and removal fittings. Downstream of this are sera dosing stations, which are used to supply the CIP systems (Cleaning In Place = automated cleaning processes) with acids and alkalis.

3. Dosing stations for outgassing disinfectants

Many disinfectants are highly gassing. This also applies to the products that are to be used at the Kegna brewery. Therefore, special attention had to be paid here to the gases so that liquid is always present at the pumps. By installing a lifting device with air jets, the gases are extracted. Furthermore, the installation of an additional safety valve secures the continuing line, and any small amounts that escape are collected in a leakage vessel.

With the modern and reliable equipment of the brewery by sera and Steinecker GmbH, the Kegna brewery, which is in the final stages of construction, will quickly be able to establish itself on the market among the top five. With a potential capacity of up to 3 million hl, Kegna can cover a good part of the growing demand for beer in Ethiopia. Experts predict that demand will increase significantly from 15 hl in 2022 to 18 hl in 2026.

sera is proud to be able to ensure that beer tastes like beer in Ethiopia as well.